A letter from the Mount Polley Team,

The Mount Polley mine team hopes that this finds you well and healthy.

The team at Mount Polley are continuing to prepare for a mine restart along with routine care and maintenance activities. We have many contractors on site and are actively recruiting talent for full operations. If you are interested in a career in mining, please contact us at hr@mountpolley.com.

As we move closer to the end of the pandemic, we look forward to offering more opportunity for community engagement and more in-person tours.

MOUNT POLLEY MINE:

CARE AND MAINTENANCE

Below we cover key bulletins that highlight areas of focus with regards to Mount Polley mine’s care and maintenance as part of mine re-start towards the operations phase:

- Environmental monitoring programs continue and are on track

- Closure research projects continue as planned

- Site water management continues, including the treatment of mine contract water through the Actiflo® water treatment plant

- Springer Pit pre-stripping operations underway

- Drilling and blasting

- Restart planning

- Mill and mine site repairs and upgrades

- Electrical systems assessment and upgrades

- Mobile equipment procurement, repairs, and upgrades

- Site cleanup and general repairs

- CANMAG magnetite plant maintenance and upkeep

ENVIRONMENTAL MONITORING UPDATE

Quarter 4 routine monitoring activities completed:

- Weekly Water Treatment Plant (WTP) water quality sampling including monthly/quarterly toxicity sampling

- Monthly water quality sampling at Hazeltine Creek

- Monthly & quarterly water quality sampling of surface & mine-affected waters including groundwater mine seepage

- Flow monitoring

- Water quality sampling and monitoring of in-pit treatment at Springer and Cariboo pits

- Monthly/quarterly site inspections

- Reporting—monthly, quarterly, annual

- Comprehensive Environmental Monitoring Plan (CEMP) development/revision

Environmental monitoring is conducted in accordance with the Environmental Management Act (‘EMA’) Permit 11678, Metal and Diamond Mining Effluent Regulations and the approved Comprehensive Environmental Monitoring Plan (‘CEMP’) requirements.

MPMC WATER TREATMENT PLANT OPERATIONS UPDATE

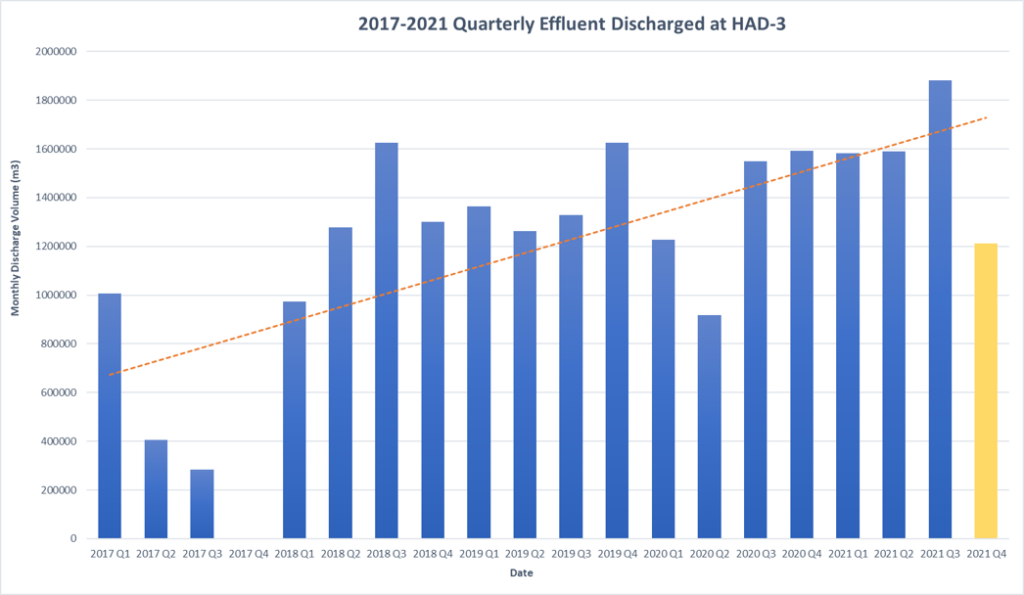

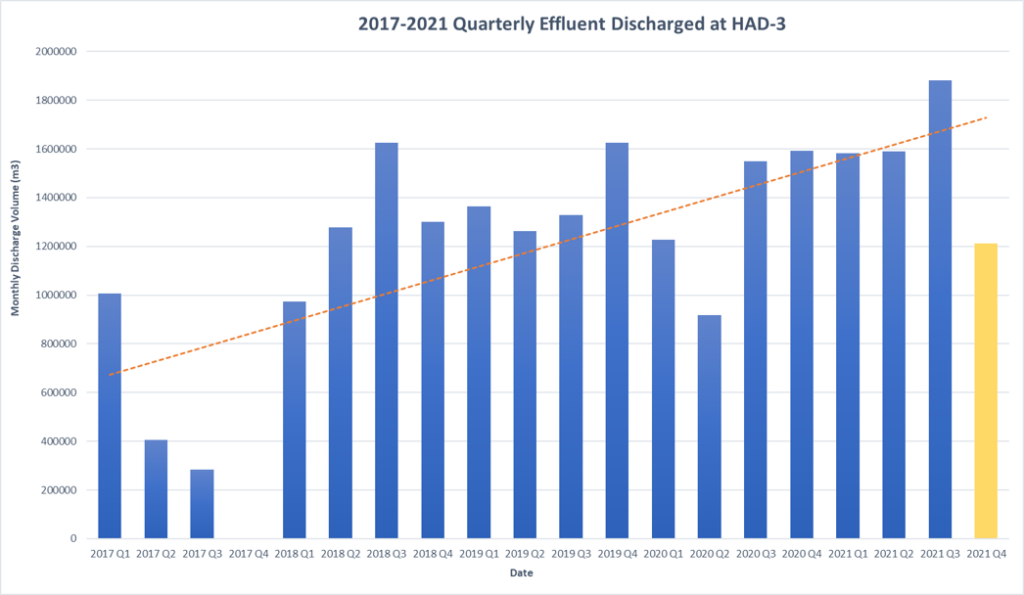

In Quarter 4 2021, the total treated water discharged to Quesnel Lake was ~1,680,605 mᵌ with an average daily discharge of ~18,267 mᵌ/day.

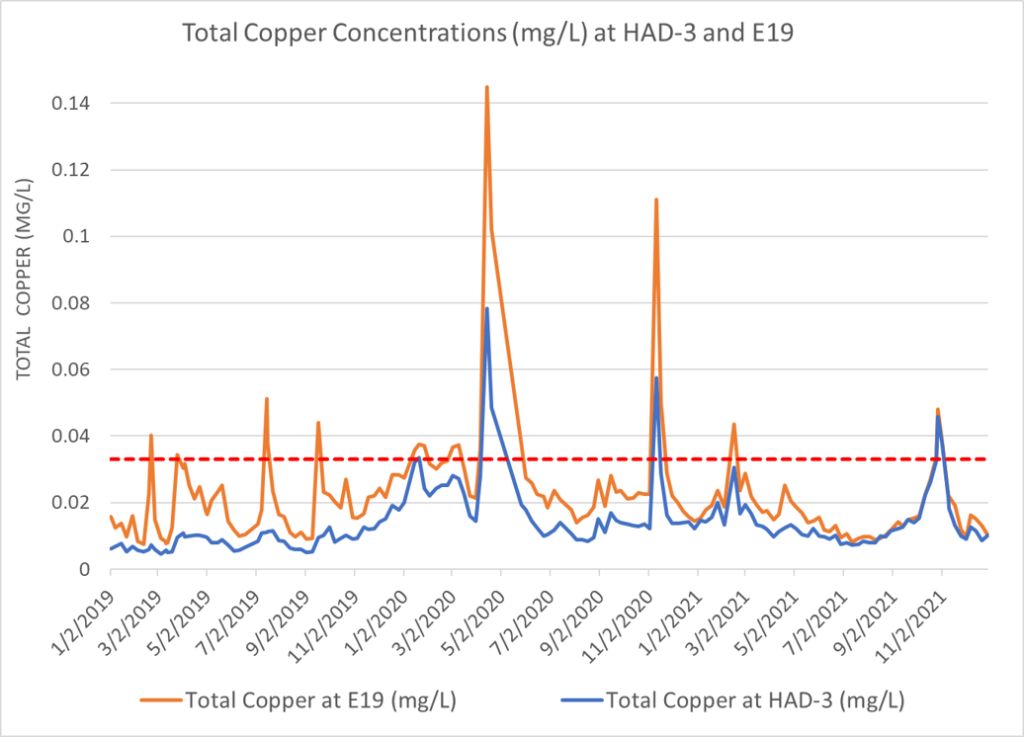

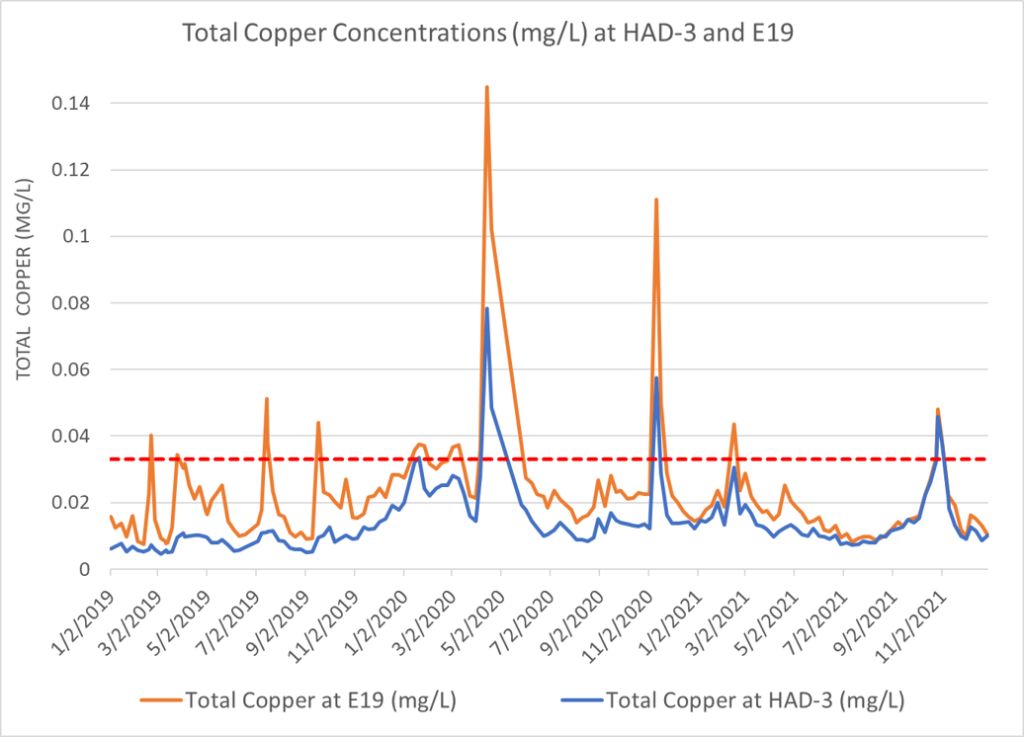

The plant operated continuously for most of the quarter. Water quality samples were collected weekly at the WTP influent (E19) and effluent (HAD-3) sites throughout the this period. Routine toxicity testing was completed on a monthly basis.

On October 27, 2021 a total copper exceedance was observed at the end of pipe sample location HAD-3, triggering a plant shut down and investigation. The root cause was found to be a combination of water chemistry changes in the source water and high throughput at the plant. The event triggered a response under our Annual Discharge Plan that included a plant shut down, placing the plant in recirculation mode (not discharging to the environment), requiring additional sampling and further investigation. Sampling was conducted in Quesnel Lake on the same day and the results indicated that the waters met the BC Water Quality Guidelines for drinking water and aquatic life.

MPMC has applied to amend its Environmental Management Act permit 11678 to extend the discharge period to Quesnel Lake from 2022 to 2025. This is an interim measure while a broader set of amendment requests are being prepared to allow for further mine development. A future permit amendment application will request that the discharge period to Quesnel Lake be extended until the end of the mine life. This amendment process is being conducted jointly with both the Ministry of Environment and Climate Change Strategy and the Ministry of Energy, Mines and Low Carbon Innovation (EMLI).

WATER TREATMENT PLANT PERFORMANCE UPDATE

HAZELTINE AND EDNEY CREEK REMEDIATION

Due to winter season conditions, small-scale remediation work was completed in Quarter 4 of 2021. Monitoring remains ongoing while planning is underway for 2022.

There is still outstanding terrestrial remediation work to be done. Planting will resume next spring to address the disturbances created by the 2021/22 construction. Some earthworks are planned for several small areas withing the Hazeltine Creek corridor and the Polley Lake shoreline. All future planned work will involve recontouring existing topographical features, planting, and monitoring.

Remediation Update Gallery – below are before and after photos that demonstrate the positive transformation of the remediation around the Hazeltine Creek and the Quesnel Lake shoreline.

RE-START UPDATE

MPMC is targeting a workforce of approximately 355 employees at full scale operations. Currently, an average of 100 personnel per day are reporting to work at the mine. This includes on-site staff and contractors. Work is currently being undertaken across the site to prepare for full operations. Present activities are focused on electrical maintenance and upgrades, mobile equipment servicing and upgrades and mill assessment, maintenance and refurbishing amongst other things. Pit operations are underway with the mined material being stockpiled or stored in the waste rock disposal sites.

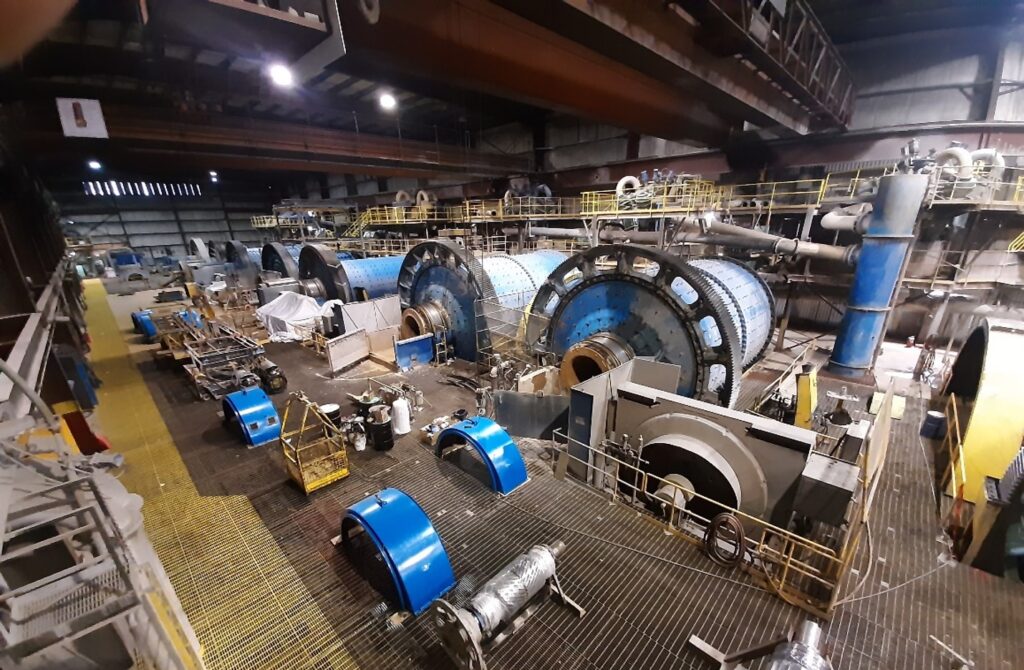

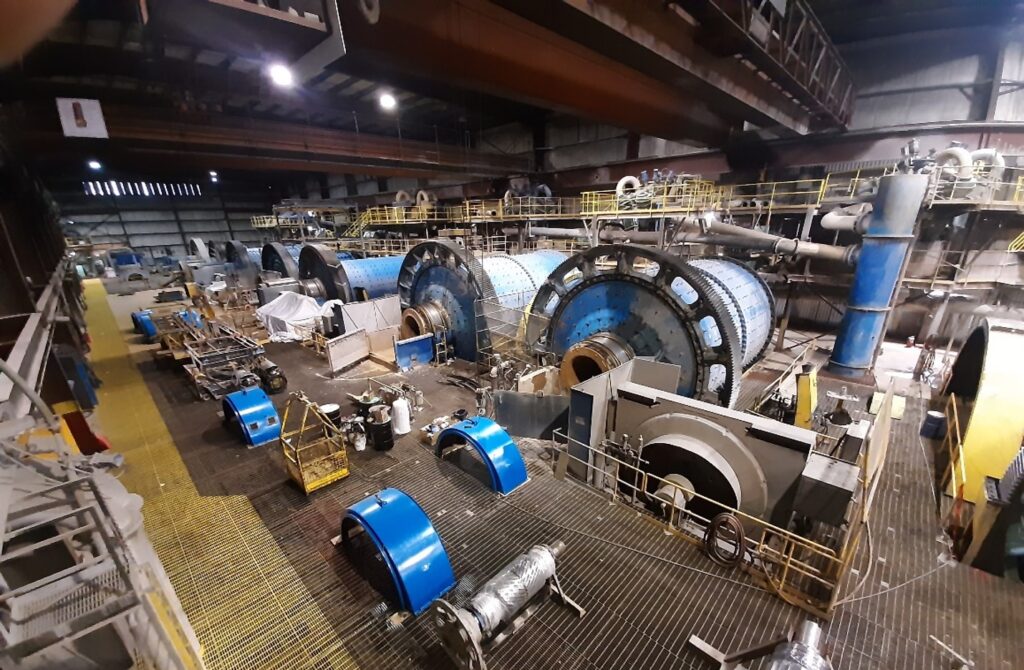

The grinding mills have been disassembled, inspected and repairs will continue to be performed before receiving a fresh coat of paint in preparation for the mine re-start in April, 2022.

Current Life of Mine Plan – Surface Mining Operations:

- 11 years mining operations in the Springer/Cariboo combined pit

- 1 year backhaul of PAG material into Springer pit after operations for subaqueous disposal

- Construction of the Tailings Storage Facility to 987 meters

MPMC EVENTS

Quarter 1, 2022

January 19, 2022 – Xatśūll Community Engagement Meeting

January 27, 2022 – Public Liaison Committee (PLC) Meeting via conference call

March 28, 2022 – Likely Community Engagement Meeting

Quarter 2, 2022

April 7, 2022 – Public Liaison Committee (PLC) Meeting via conference call

RESOURCES

BC Mine Information Page: https://mines.nrs.gov.bc.ca/

BC Ministry of Environment Natural Resource and Enforcement Database: https://a100.gov.bc.ca/pub/ocers/searchApproved.do?submitType=menu

Interested applicants may send their resume and cover letter to: hr@mountpolley.com

Any questions regarding the Community Update, please email Gabriel Holmes at gabriel.holmes@mountpolley.com